ECOCONTACT®: the alternative solution for electrical contact maintenance. A patented technology developed by AMC Group.

THE ORIGIN OF ECOCONTACT®

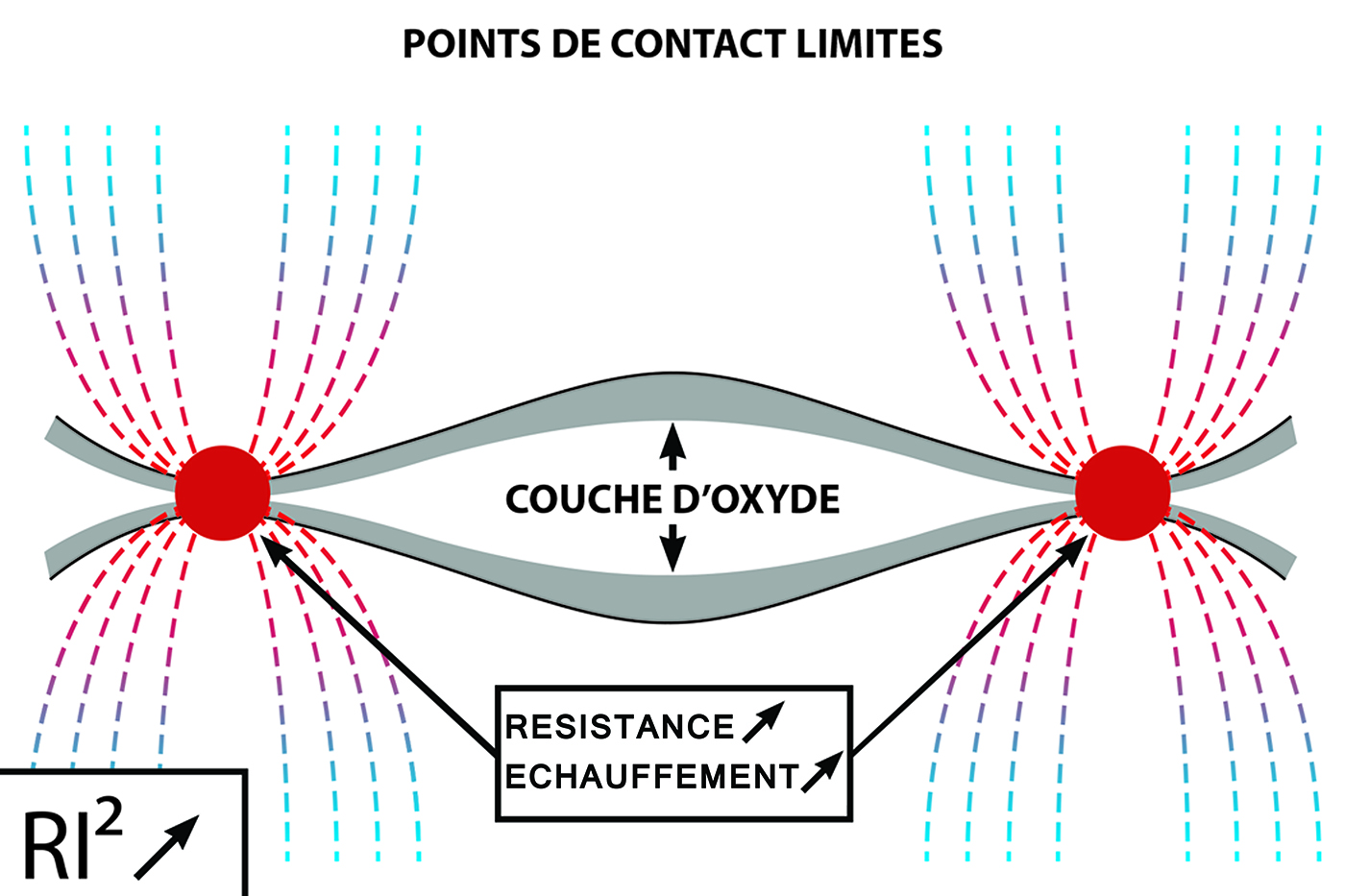

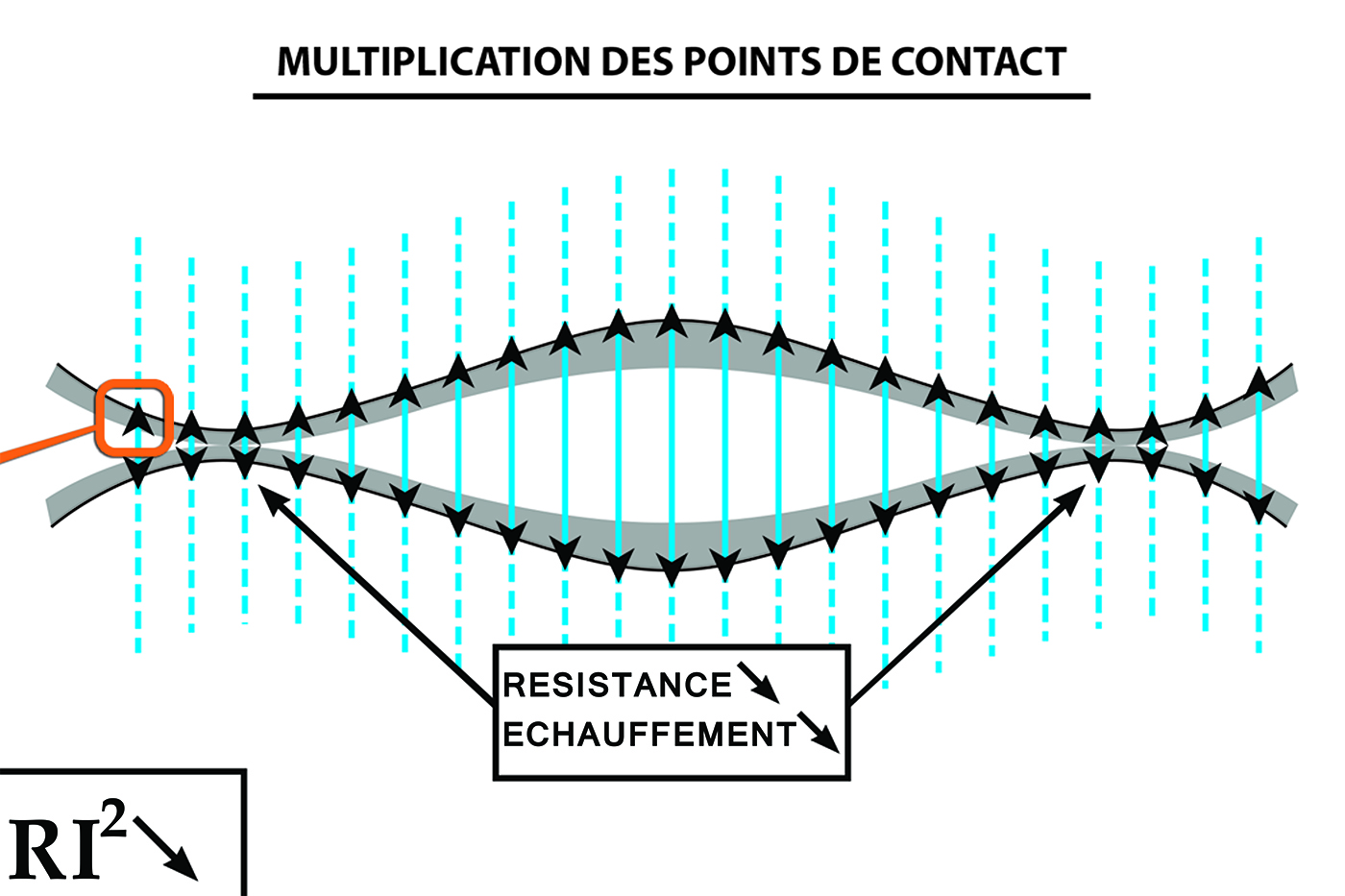

Based on the observation that downtime & maintenance costs for bolted connections in electro-intensive circuits are a major problem for industrials; AMC ETEC has been looking for an ultimate solution.

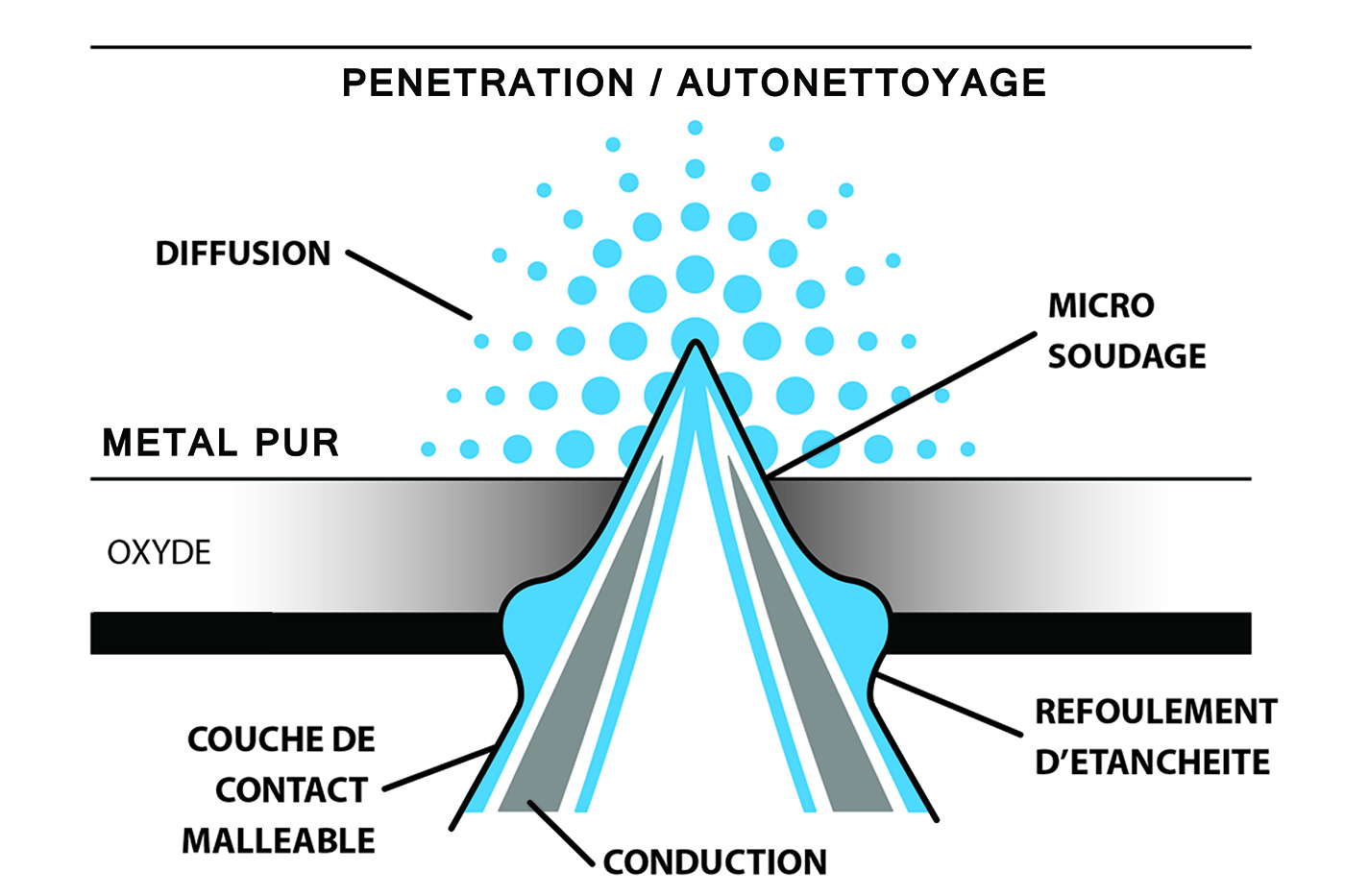

The main idea was to optimise as much as possible the whole process in order to increase considerably the performances and to reduce the necessity of cleaning contacts.

The very first solution developed by AMC ETEC was the micro-deforming silver sheets, known for their efficiency in copper, but the worldwide market aluminium emergence has convinced our R&D team to create a universal product, also able to process copper and aluminium contacts all around the word. Then has emerged the ECOCONTACT® foam.

Eight years of EDF operating experience, 100% of satisfied customers and several tens of thousands of contacts installed all around the world have definitely validated the success and achievement of the ECOCONTACT® foam.